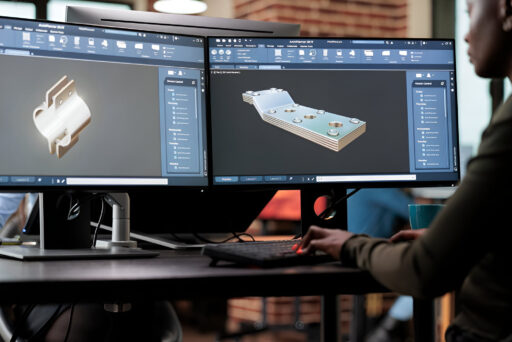

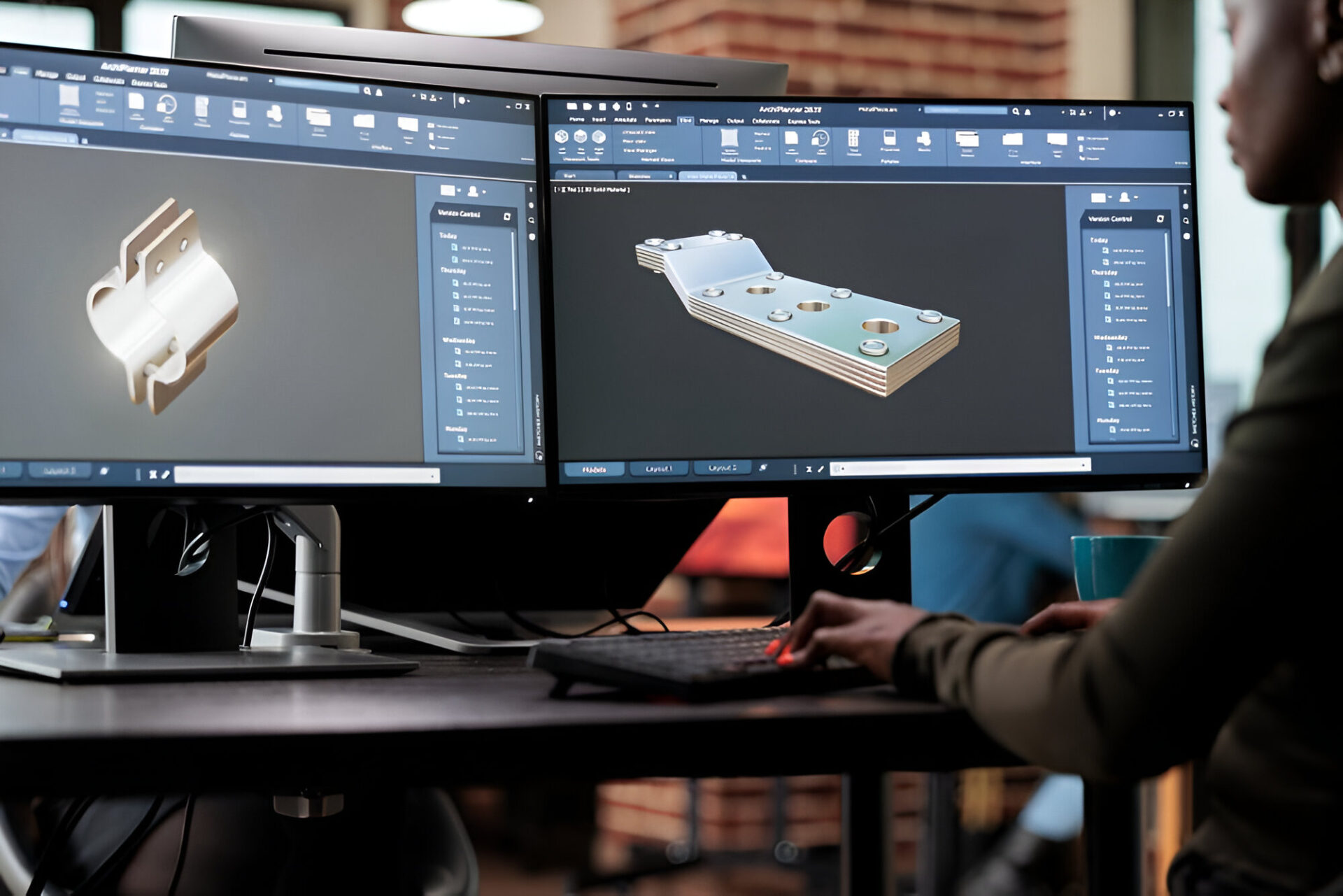

3D modeling and rendering are vital for creating digital objects and environments. They let designers create detailed virtual prototypes. They make quick design changes and precise tweaks without using physical materials. This approach speeds up development, cuts costs, and improves quality. Using 3D modeling and rendering, companies can visualize their products. They can see realistic lighting and textures. This helps them spot flaws early. It allows them to make informed decisions before production.

3D Modeling and Rendering

3D modeling is creating a 3D digital object with software. It involves creating shapes, adding textures, and defining details to make a complete model.

Rendering takes 3D models and turns them into 2D images with realistic lighting and textures. This step is crucial for visualizing how the model will look in real life.

These techniques are crucial in various industries, especially during the prototyping process. They allow designers and engineers to visualize products before building them. This helps find flaws early and make adjustments.

Tools for 3D Modeling and Rendering

Several software tools are commonly used in 3D modeling and rendering:

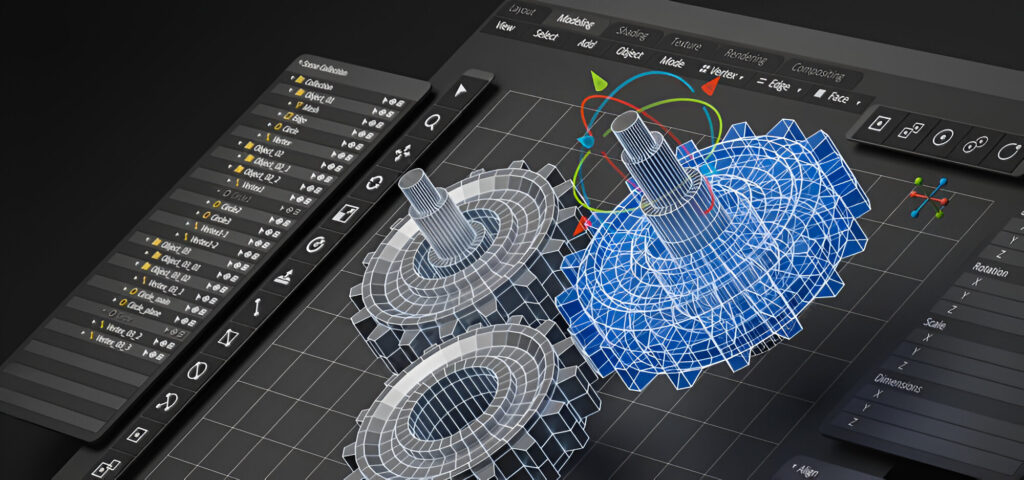

Blender: A free, open-source tool for modeling, rendering, and animation. Its extensive features make it a favorite among independent designers.

SketchUp: Initially created for architectural design, it now serves many purposes. It offers both free and paid versions with user-friendly features.

SolidWorks: SolidWorks is a powerful CAD program. Engineers use it to create detailed models based on geometric parameters. It allows users to create assemblies that respond to design changes effectively.

ZBrush: It is known for its digital sculpting. It allows for the intricate detailing of models. ZBrush is widely used in industries that require high levels of detail.

Maya: It’s popular for animation and game development. It has advanced modeling and rendering tools for creating dynamic visuals.

The Traditional Prototyping Process: Challenges and Limitations

Traditional prototyping methods have served industries for years. But, they have significant challenges:

Common Traditional Prototyping Techniques

Traditional prototyping typically involves several key methodologies:

- Hand-Drawing: This method is often used for initial concept sketches. Hand-drawn designs allow for quick idea generation. But they lack precision. This can lead to misinterpretations at later development stages.

- Clay Modeling: This hands-on method lets designers make detailed, 3D models of their ideas. However, clay modeling is time-consuming and can be costly. The materials and skilled labor are expensive.

- Physical Prototypes: Creating physical models often requires specialized tools and materials. This process can be costly and labor-intensive. It’s worse if many design iterations are needed.

Key Challenges of Traditional Prototyping

High Prototype Costs:

Traditional prototyping often requires costly tools, molds, or subtractive manufacturing methods. This makes small production runs particularly costly, as tooling expenses are spread over fewer units. For example, a single injection mold can cost thousands. So, it is impractical for low-volume projects.

Long Lead Times :

Traditional prototyping has many steps. They are designing, fabricating tools, and assembling the final product. Each of these stages can take weeks or even months to complete. Such long lead times delay product launches and limit opportunities for rapid iteration. In industries like technology or fashion, this lag can result in missed market opportunities.

Limited Flexibility for Design Changes:

Making design modifications through traditional prototyping can be both expensive and time-consuming. Even small changes may need a complete redo of the tooling setup. This makes it hard to test different design options. This rigidity can stifle creativity and discourage teams from exploring innovative solutions.

Resource Intensive:

Traditional methods waste time, money, and materials. We could have used those resources better. The need for skilled labor to craft prototypes adds another layer of complexity and cost.

Applications Across Industries

3D modeling and rendering have applications across many sectors.

Industry examples

Consumer Electronics:

Companies use these technologies to design sleek devices with improved functionality. For example, smartphone makers use 3D modeling to optimize component placement in their compact designs.

Automotive:

Engineers create detailed vehicle models to test aerodynamics before manufacturing. This process reduces the number of physical prototypes needed during development.

Architecture:

Architects visualize buildings in realistic settings before construction begins. This visualization helps clients understand the final product better.

Fashion:

Designers create virtual clothing samples to showcase collections without physical garments. This approach allows for quick adjustments based on feedback from stakeholders.

Healthcare:

Medical professionals use 3D models for surgical planning or creating custom prosthetics. These tailored solutions greatly improve patient care by providing personalized options.

Choosing the Right 3D Modeling and Rendering Service

When choosing a 3D modeling and rendering provider, consider these factors:

Important Factors

Cost: Ensure that the pricing aligns with your budget while still providing quality work. Compare quotes from different providers to find the best value.

Software Expertise: Check if they are proficient in the tools you prefer or require for your project. Familiarity with industry-standard software indicates reliability.

Industry Experience: Look for providers who have worked on similar projects in your industry. Their experience can lead to better outcomes tailored to your needs.

Scalability: Ensure they can handle projects of varying sizes as your needs grow. A provider that can scale with your business will save you time in the long run.

Evaluating Portfolios

When reviewing potential providers:

1. Look at their past projects to assess their quality.

2. Check client testimonials to gauge satisfaction.

3. Ask about their design process to ensure it aligns with your expectations.

Questions to Ask Before Hiring

Before making a decision, consider asking:

- What is your typical turnaround time?

- Can you provide references from previous clients?

- How do you handle revisions?

Future of 3D Modeling in Product Prototyping

The future of 3D modeling is bright with emerging trends that promise even more innovation:

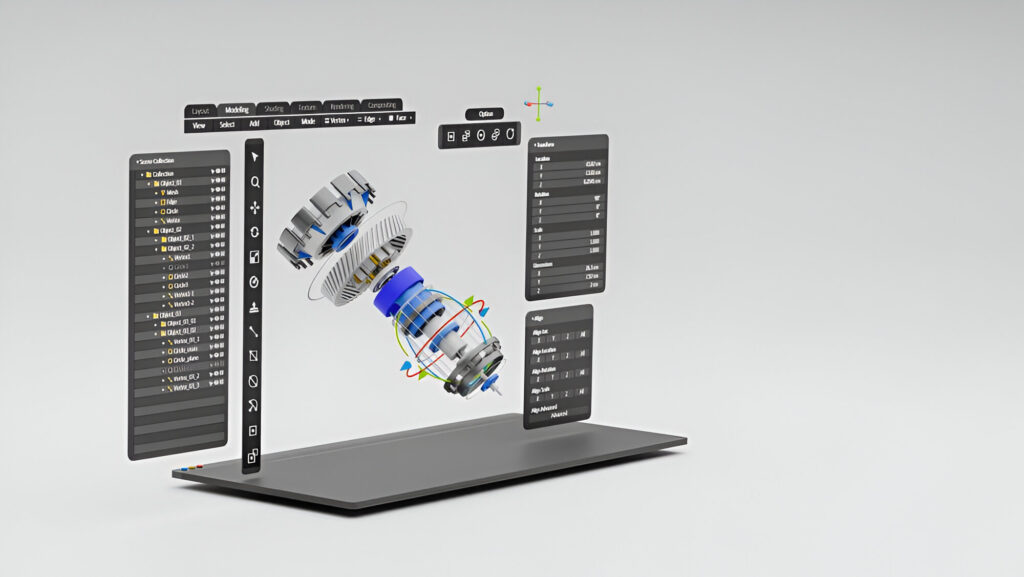

1. AI Integration: Artificial intelligence will streamline design processes by automating repetitive tasks. This integration can lead to faster project completion times while maintaining quality standards.

2. VR/AR Visualization:

VR and AR will let designers interact with their models in immersive environments. This technology boosts team collaboration. It provides an interactive experience in design reviews.

3. Collaborative Cloud Tools:

These tools will enable teams from different locations to collaborate effectively on projects. Cloud-based platforms facilitate real-time updates and feedback among team members.

4. Predictive Modeling:

This tech will predict product performance, based on simulated conditions, before production. It will reduce risks with new designs.

Conclusion:

3D modeling and rendering can greatly improve product prototyping in many industries. Knowing their benefits over traditional methods, businesses can innovate faster. They can also cut costs and enhance the quality of products. Whether you’re an established company or a startup, use these technologies. They will help you compete in today’s quick-moving market.